Understanding the Background Of Cabinet Construction

High quality cabinets should not only look gorgeous, but they should also be functional and built with top strength and durability. Unfortunately, sometimes we see poor cabinet construction.

The good news is that this can easily be avoided. Below, we’ve highlighted a basic overview of kitchen cabinet construction along with explaining some key terms to understand so you can choose the best cabinets.

Basic Cabinet Styles

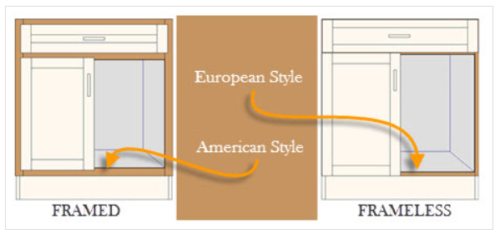

The way a cabinet is built is dependent upon the manufacturer; however, all cabinets come in two different designs: framed or frameless. The biggest difference between the two comes down to the face frame.

Framed vs. Frameless Cabinetry

Face-framed cabinets (also known as framed cabinets) include wood pieces around the front outer edge of the cabinet, which ‘frame’ it (hence the name).

The design functionality behind framed cabinets is that it helps the entire cabinet to remain square and sturdy. Framed cabinets also offer a more classic look and are typically seen in American households. You can; however, get some variety and uniqueness with door overlay (we’ll get to that later on in this post).

Due to the cabinet construction, the inside portion of the frame will extend past the inside edges of the box causing some blockage with the cabinet opening.

Frameless cabinetry is also known as full access simply due to the fact that frameless cabinets offer greater accessibility by completely eliminating the face frame. This style is very popular in Europe; however, we are seeing this trend emerge here in the United States.

In the frameless cabinet construction process, flat panels of engineered wood (usually either particle board, plywood, or medium density fiberboard) are precisely constructed using dowels and glue.

Frameless cabinetry offers these benefits over traditional framed cabinets.

- They have no center stile allowing for more room and storage.

- Due to more precise construction, frameless cabinets have a tighter fit with less gaps between doors and drawers.

- Usually the shelves are adjustable, so you can store that awkward sized box.

- They have a thicker box construction which increases the stability.

- Typically sizes include base cabinet manufacturing on 3-inch increments from 9-inches up to 48-inches.

What Cabinet Design Should You Choose?

That answer is entirely up to you and what you’re looking to do with your space; however, we do have some quick tips for you:

Frameless Cabinetry

- Sleeker look

- Contemporary/European style

- Provides full access to cabinet interior and drawers

- Requires a more skilled installation

Framed Cabinetry

- Traditional/American style

- Face frame reinforces cabinet alignment

- Easier to install

3 Common Cabinet Construction Elements & Methods

Similar to cabinet design styles, cabinet construction methods are left up to the manufacturer. In addition to knowing some key terms (which we’ve highlighted below), it’s important to know that cabinet construction can affect the level of quality, durability, and longevity of cabinets.

All About Overlays

Door overlay is defined as how much a cabinet door covers or overlaps the face frame. Cabinet doors can have three different overlays:

- Full Overlay refers to the doors and drawers covering the face frame entirely. Frameless cabinets typically come in full overlay. With a lower cost, full overlay cabinet doors provide the greatest amount of storage.

- Partial Overlay (Traditional) means the cabinet doors and drawers only partially cover the frame. This is the most common and least expensive option. Typically, the overlay will leave about 1 to 1 ¼-inch between doors and drawers.

- Full Inset is when cabinet doors and drawers are designed to fit within the face frame. On occasion, frameless lines will embody the full inset. This smooth and clean look will probably increase the cost of your cabinets and can, unfortunately, leave smaller storage spaces.

Other door details can include raised panel, which is when the center panel of the door is elevated. Recessed panel which is where the center panel is set in lower than the door frame.

Our designers also see slab door styles as being very popular. A slab door style is a solid, flat front door with no panel or face frame.

Dovetail Construction

This term has to do with joinery or how the various wood parts of a cabinet are joined together. While there are a few different methods, we often get asked about dovetail and why we recommend it.

Dovetail construction (or dovetail joints) is one of the strongest ways to join two boards together. Why? In incorporating dovetail, the ends of the two boards have v-shaped cutouts that fit in and correspond to the notches on the adjoining wood panel. They are interlocked together on right angles.

Full vs. 3/4 Extension Drawers

We’ve been talking a lot about cabinets and doors, and now it’s time to give drawers some love.

When designing a new kitchen or remodeling an existing one, it’s important to think about functionality. This comes down to drawer details, specifically deciding on how far you want the drawers to extend out.

With a full drawer extension, you’ll be able to open drawers the full length of the slide. This allows for greater access, especially if you’re using this drawer to hold smaller items.

¾-drawer extension means the drawer slide will only come out three-quarters of the entire length, leaving part of the drawer in the cabinet. While it doesn’t provide as much access, it is a good economical option.

Cabinet Installation

To ensure that cabinets are properly installed, strong, durable, and will last for years, buying fully assembled cabinets that are assembled at the factory is the best route to go. In doing so, these cabinets will be built with industrial techniques that increases the strength of them. When shipped from the factory, the cabinet is a full unit with doors and drawers intact, and will be ready to install as soon as it arrives.

However, there is an alternative: ready-to-assemble (RTA) cabinets.

What are Ready-to-Assemble (RTA) Cabinets?

RTA cabinets have many benefits including:

- All plywood construction

- Nice finish and polished door profiles

- Simple offering

If you do choose to go the RTA route, there are some items that you should know before ordering:

- They are imported from overseas

- Assembly is required, with an average assembly time of 20 minutes per cabinet

- Replacement parts can be hard to order

- If inventory is low, your order could take months to ship

- Usually you have to pre-pay before they ship

Typical Cabinet Construction Sizes

In addition to the basic design elements of kitchen cabinet construction and installation, the other components to understand are the “building blocks”, or main components of cabinets.

Base Cabinets

These types of cabinets are mounted on the floor and help to support the countertops. Base cabinets usually come standard with a 24-inch depth.

A great example of using base cabinets in a unique and custom way is to incorporate them into a kitchen island.

Wall Cabinets

Like the name implies, wall cabinets are mounted directly to the wall and have no connection to the floor. These cabinets are usually located above countertops and ovens. The standard depth of wall cabinets are 12-inches. There is the possibility of a 24-inch depth but that applies to select appliance cabinetry only.

Vanity Cabinets

On a basic level, vanity (also known as tall or pantry) cabinets are tall versions of base cabinets. Vanity cabinets stand on the floor and can either be free-standing or connected to a wall or base cabinet. A typical vanity-sized cabinet either has a depth of 18-inches or 21-inches.

For all three cabinet types, the widths start at 9-inches and will max out at 60-inches. Of course, all typical cabinet sizes will vary by the cabinet manufacturer and SKU. We ask that you work with your contractor or builder to ensure that the right cabinet and size is ordered.

Making Your Cabinets Look Beautiful: The Finishing Process

The final stage in the cabinet construction process is finishing. Getting the desired look and feel of your cabinets depends upon the type of finish, wood type, and the cabinet maker’s capabilities. Fortunately, a lot of cabinet assembly plants have modern day technology which allows for a variety of finishes to be applied to cabinets.

Paint

One of the biggest trends right now for both kitchen and bathroom cabinets is paint. Why? Paint allows you to have a limitless color pallet. You also won’t be limited to the earth tones that you often see with common wood stains. For example, you can see how this kitchen incorporated yellow paint.

Stain

Stains are a beautiful option if you love the natural look of wood. With a wood stain, a topical color treatment is applied. While it stains the outer layer of the wood, it will also bring out the natural grain pattern.

Glaze

Contrary to stain, a glaze allows the surface detail to shine. Typically, a glaze is a pigmented coating that’s applied overtop a paint or stain. It’s often used to enhance the look of cabinets. This is a more manual process than other cabinet finishing types simply because the glaze is hand wiped off.

In reality, these are just a few finish options to choose from. We recommend that you work with your builder, distributor, or cabinet company directly to see the variety of finish options offered in your door style.

Partnering With The Best

Here at H.J. Oldenkamp, we are proud to offer the nation’s most popular cabinet lines which include:

Merillat: Masterpiece & Classic

Mid Continent Cabinetry

Vista Cabinetry

Fabuwood

QualityCabinets & Woodstar

Kountry Wood Products

From our semi-custom cabinetry to value series, we offer a cabinet line that will fit your needs and budget. Plus, most of our cabinet lines offer a variety of door styles, accessories, and storage options – everything you need to create your dream space.

If you have any questions about cabinet construction or our cabinet lines, please feel free to call our team today at 800-462-6047 and we’ll be happy to answer all of your questions.

Recent Posts

- Top 3 Tips for 2021 Home Renovations May 4, 2021

- Corian® Design – KBIS Webinar Links February 23, 2021

- Save 8% on Fabuwood Today October 14, 2020

- Now Stocking New Calacatta Novello October 14, 2020

- Interior Design: The Element of Texture October 9, 2020